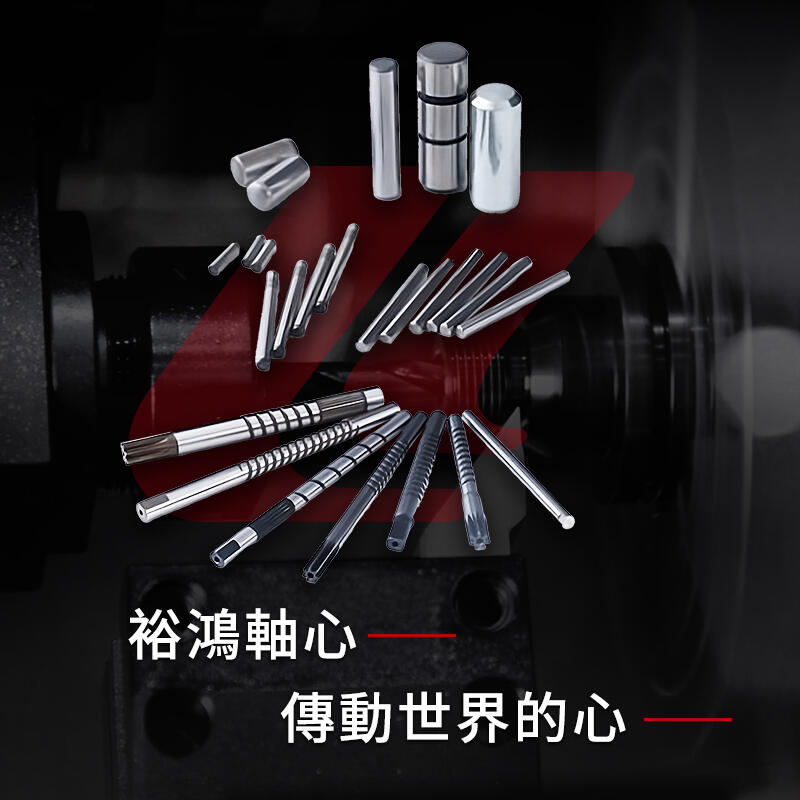

Service Introduction

Centerless Grinding & CNC Sliding Head Lathe OEM

Yu Hung CNC sliding head lathe OEM services focus on providing clients with high-precision and high-quality machining solutions. The company is equipped with advanced CNC sliding head lathe machinery capable of achieving exceptional machining accuracy, ensuring that the dimensions and shapes of each part strictly comply with design specifications. also offers centerless grinding services that concentrate on high-precision and efficient processing of cylindrical workpieces. With advanced centerless grinding equipment and an experienced technical team, we can meet the diverse needs of our clients. centerless grinding technology achieves high-precision size control of 1 μm, ensuring that every workpiece meets strict tolerance requirements. Equipped with advanced machinery and automated production lines, we guarantee efficiency in mass production, reduce lead times, and lower production costs. Our centerless grinding services achieve excellent surface roughness, meeting various high standards for surface quality. With our professional technology and efficient production capabilities, Yu Hung is committed to providing outstanding CNC sliding head lathe OEM services and centerless grinding, making us your reliable partner.